PACT is a commercial construction company in Perth specialising in the Tier 2 space. As a commercial builder, we like to provide insight into specific construction stages. Here, we take you through the crane dismantling process on one of our projects – ABN Group Headquarters in Leederville, which is a commercial construction project incorporating a state-of-the-art ground floor retail showroom, a multi-level office, ground floor commercial tenancies, extensive end-of-trip facilities and approximately 160 car bays.

Watch the video or read the transcript of the video below:

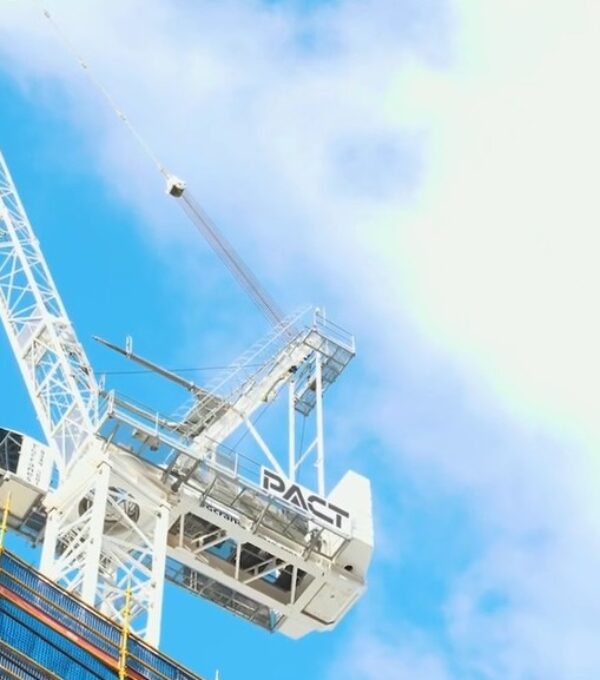

Hey, my names Luca. I’m one of the Site Managers at the Leederville Office Development and today were going to cover one of the key milestones for this project: the removal of our tower crane.

The removal of this tower crane was booked eight months ago due to the fact that we had to have Western Power shut down our high voltage power lines within the City of Vincent. The removal of this tower crane was one of our most high-risk processes, and safety was our number one priority. The process involved our construction team sequencing all our critical crane heavy works and programming that against our construction schedule.

The date was picked, the submissions were made with Western Power and the City of Vincent, and that date was hit. Vincent Street is actually under the control of Main Roads and is the main arterial highway during the peak hour periods.

Our tower crane was programmed to be removed on a Saturday and Sunday, with the public holiday on the Monday being our backup plan. Prior to any form of works starting on the Saturday morning, every single construction member involved in the process of this tower crane removal met in our site office for a 6:30 toolbox talk. One of the key processes involved in this was to talk through the entire sequence involved in this weekend and the key aspects involved in the high-risk areas. One of the main reasons why we perform a toolbox prior to any form of works beginning is simply to keep an open dialogue of communication. The biggest difficulty is losing information of information crossing paths and not being communicated clearly. The best way to do that is bringing every single team member together to discuss the entire process, all the hazards, everyone’s roles, and making sure everyone’s on the same page.

Works begin around 7oclock, with our traffic management team shutting down both ends of Vincent street. The next step involved the termination of our high voltage power lines. As a secondary check, Western Power had a set of onsite contractors, who physically dead-tested the power lines. Western Power have some minimum clearances associated with working near live power lines, but they also gave us a minimum clearance of three meters to be next to a dead power line. From a safety perspective, we chose to work within a 4.5-meter minimum clearance.

Due to the height of our tower crane, we had to mobilise a three hundred tonne mobile crane to physically take down our tower crane. The process of a tower crane removal is generally dictated by the supplied manufacturers removal sequence. The removal of a tower crane generally starts with fifty percent removal of the rear counterweights, followed by the main boom, then the balance of the counterweights, the central slew deck, and then the entire mast tower. For every single lift, we had an entire sequence programmed. This sequence not only dictated every single lift, it also dictated every single semi-trailer that was on the ground awaiting to receive individual components.